The importance of controlled atmosphere

The use of controlled atmosphere in Chile began in the 90’s with the arrival of Transfresh. From there, exporters who know and use this technology have managed to maintain the condition and quality of their fruit when exporting to Europe, the United States, Asia, among others

Controlled atmosphere technology is based on constantly maintaining the concentrations of carbon dioxide and oxygen in a given environment (in this case, a reefer container). In this way, the respiratory rate of the fruit decreases, thus delaying its maturity, maintaining firmness, avoiding the proliferation of fungi and problems with prolonged storage. However, these CO2 levels are not the same for all commodities.

The choice of one set point or another varies depending on many factors such as: the species, variety and place of production. For example, thanks to various studies and investigations carried out, Liventus was able to validate that the concentration of CO2 required for avocados produced in Chile is different from that of those produced in Colombia. The same happens for blueberries produced in the north and south of Peru.

In search of the best set point for plums

As for stone fruits, since they are not one of Chile’s main export products, fewer and fewer studies are being carried out regarding their problems in the field, packing and post-harvest. Little by little, the agricultural sector has been leaving aside the research, and staying with the “usual” way of carrying out the export process, sticking more to books and studies carried out abroad, not necessarily agreeing with the situation of local production, so they are not 100% effective when put into practice.

Liventus managed to capture this gap in the industry and for 8 years it has been assisting stone exporters by carrying out various studies to discover which is the best set point, especially for plums.

Commonly, the process of exporting plums was carried out in reefer containers with a controlled atmosphere of 5% CO2. Liventus, seeing that the plums continued to arrive with prolonged storage problems, carried out studies and investigations, elucidating a new, more effective concentration. This is how the industry began to use a controlled atmosphere of 10% CO2 and 5% O2..

Latest studies of Set Points in plums

Today, after new studies and investigations and thanks to the help and confidence shown by exporters in the plum industry, Liventus developed a new set point. This maintains the condition and quality of the plums for longer, maintaining their firmness, reducing the presence of translucent pulp, the development of mealiness and the presence of mycelia.

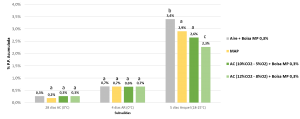

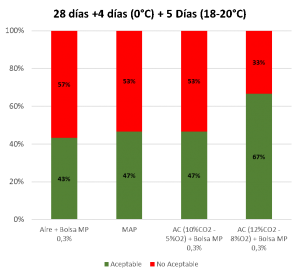

A study was carried out comparing the three most used technologies in the post harvest handling of plums: (Air + Macro perforated bag, MAP Bag, CA (10-5) + Macro perforated bag and CA (12-8) + Macro Bag perforated) seeking to evaluate which one is more efficient for the longer transit times that the industry is facing today. Fortunately, the results were very positive.

By increasing the concentrations of carbon dioxide in the container, this decreases the respiratory rate of the fruit, thus delaying its ripening, however, with a greater amount of CO2 there is a greater “dormancy” in the fruit, which helps to reduce the weight loss considerably.

Figure 1: Study conducted by Liventus. Comparison % weight loss between Regular Air + Macro perforated bag 0.3%, MAP Bag, AC (10-5) + Macro perforated bag 0.3% and AC (12-8) + Macro perforated bag 0.3%

These and other equally positive results in terms of internal browning, visual dehydration and firmness make us aware of the need for the industry to seek limits and renew the technical aspects established decades ago.

Figure 2. Study conducted by Liventus. Comparison of acceptable and non-acceptable fruits between Regular Air+Bag Macro perforated 0.3%, MAP Bag, AC(10-5)+Bag MP 0.3% and AC(12-8)+Bag MP 0.3%.

These and other equally positive results in terms of internal browning, visual dehydration and firmness make us aware of the need for the industry to seek limits and renew the technical aspects established decades ago.

Latest studies of Set Points in plums

Today, after new studies and investigations and thanks to the help and confidence shown by exporters in the plum industry, Liventus developed a new set point. This maintains the condition and quality of the plums for longer, maintaining their firmness, reducing the presence of translucent pulp, the development of mealiness and the presence of mycelia.

A study was carried out comparing the three most used technologies in the post harvest handling of plums: (Air + Macro perforated bag, MAP Bag, CA (10-5) + Macro perforated bag and CA (12-8) + Macro Bag perforated) seeking to evaluate which one is more efficient for the longer transit times that the industry is facing today. Fortunately, the results were very positive.

By increasing the concentrations of carbon dioxide in the container, this decreases the respiratory rate of the fruit, thus delaying its ripening, however, with a greater amount of CO2 there is a greater “dormancy” in the fruit, which helps to reduce the weight loss considerably.

This entry is also available in:

![]() Español

Español